A pool pump is essential to keeping your pool water clean and properly circulated. However, when the pump isn’t working correctly, it can lead to a plethora of issues, from poor water quality to complete system failure. Understanding common pool pump issues is key to quickly identifying the root cause and determining the appropriate solution. Whether it’s a power supply problem, a blockage, or a motor overload, having the knowledge to troubleshoot can save you time and possibly prevent the need for a costly visit from a pool professional.

When addressing pool pump troubleshooting, start by ensuring the pump is receiving power and that all electrical connections are secure. A tripped circuit breaker or a disconnected plug might be all that stands between you and a functioning pump. If the power supply is intact but the pump fails to start or makes unusual noises, inspect the pump basket and skimmer water levels; a low water level could lead to the pump sucking in air, which diminishes its efficiency and can damage the pump over time.

Continual pump issues can be frustrating, but with a systematic approach, many of them can be resolved without professional assistance. Regular maintenance such as clearing clogged filters, ensuring tight seals, and checking for leaks will keep your pump running optimally. However, if these steps don’t resolve the problem, don’t hesitate to contact a pool professional to avoid risking further damage to your system. With the right troubleshooting tips at your disposal, you can identify common issues and keep your pool pump in top shape.

Assessing Pool Pump and Water Level Issues

When your pool pump is failing to operate correctly, checking the water levels along with the integrity of the pump system components is crucial to identify and rectify issues causing low water flow or irregular suction.

Checking Water Levels and Skimmer Basket

Ensure your pool water level is at least halfway up the skimmer box to facilitate proper suction. Check the skimmer basket is clear of debris which can restrict water flow and cause the pump to work harder, leading to potential malfunctions.

- Skimmer Basket: Empty and rinse to remove debris.

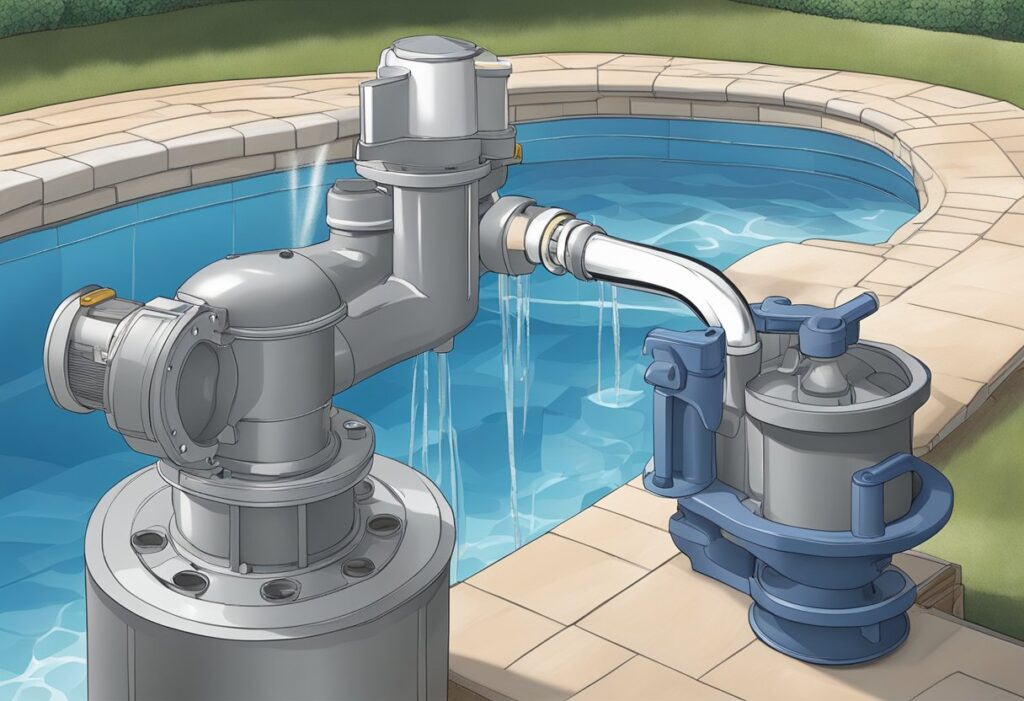

Evaluating Pump Lid and O-Rings for Air Leaks

An air leak might occur if your pump lid or the o-ring that seals it is compromised. Inspect the pump lid for cracks and scrutinise the o-ring for signs of wear or damage. A damaged o-ring can lead to air entering the system, reducing suction and impairing pump efficiency.

- Pump Lid: Look for signs of damage or wear.

- O-Ring: Replace if it appears brittle or damaged. Apply silicon pool lube to ensure a good seal.

Inspecting the Strainer Basket and Pump Basket

Your strainer basket and pump basket play pivotal roles in the cleaning and maintenance of your pool. They should be free of debris to maintain optimal water flow. A clogged basket can cause low water flow and put additional strain on the pool pump.

- Strainer Basket: Clean regularly to prevent clogs.

- Pump Basket: Ensure it is not damaged and sits properly in place.

Electrical and Motor Troubleshooting

In addressing issues with your pool pump, it’s crucial to safely evaluate electrical connections and the pump motor. A systematic approach can help you pinpoint and correct common problems.

Diagnosing Electrical Problems

Your pool pump’s operation depends heavily on consistent power supply. Begin by checking your circuit breaker; a tripped breaker suggests an electrical overload or fault. Next, inspect the breaker box for any signs of damage or wear. If a tripped breaker won’t reset, this could indicate a more serious electrical problem.

Routine checks should encompass:

- Wiring: Ensure all connections are tight and secure. Loose wires can cause intermittent power or complete failure.

- Power supply: Verify that the voltage aligns with the pump’s requirements. Incorrect voltage can harm the pump motor.

- Blown fuses: Replace any that may have blown due to overloading or power surges.

If you’re uncertain about these steps or discover signs of charred wires or an overloaded circuit, contact a licensed electrician to fix the issue safely.

Addressing Motor and Capacitor Issues

The motor of your pump is its beating heart, and issues here can render the entire system inactive. A humming sound without activation often points to a seized or jammed motor, or a faulty capacitor—the component that gives the motor its start or run capability.

When troubleshooting motor complications:

- Capacitors: Carefully inspect these for bulges or leaks, as these signs suggest a need for replacement. Be aware that capacitors can hold charge even when powered down, so proceed with caution.

- Overload protection: Check the motor for an overload protection switch. If this has tripped, the motor may have overheated. Wait for it to cool before resetting.

Wire sizes should match the specifications of your pump to ensure proper current flow and to prevent overheating. If you’re unsure how to handle these issues or if the problem persists after replacing capacitors and resetting switches, a professional should inspect the pump motor to diagnose and remedy complex motor troubles. Remember, working with electricity requires respect for its dangers and adherence to safety standards.

Identifying and Resolving Flow and Leak Problems

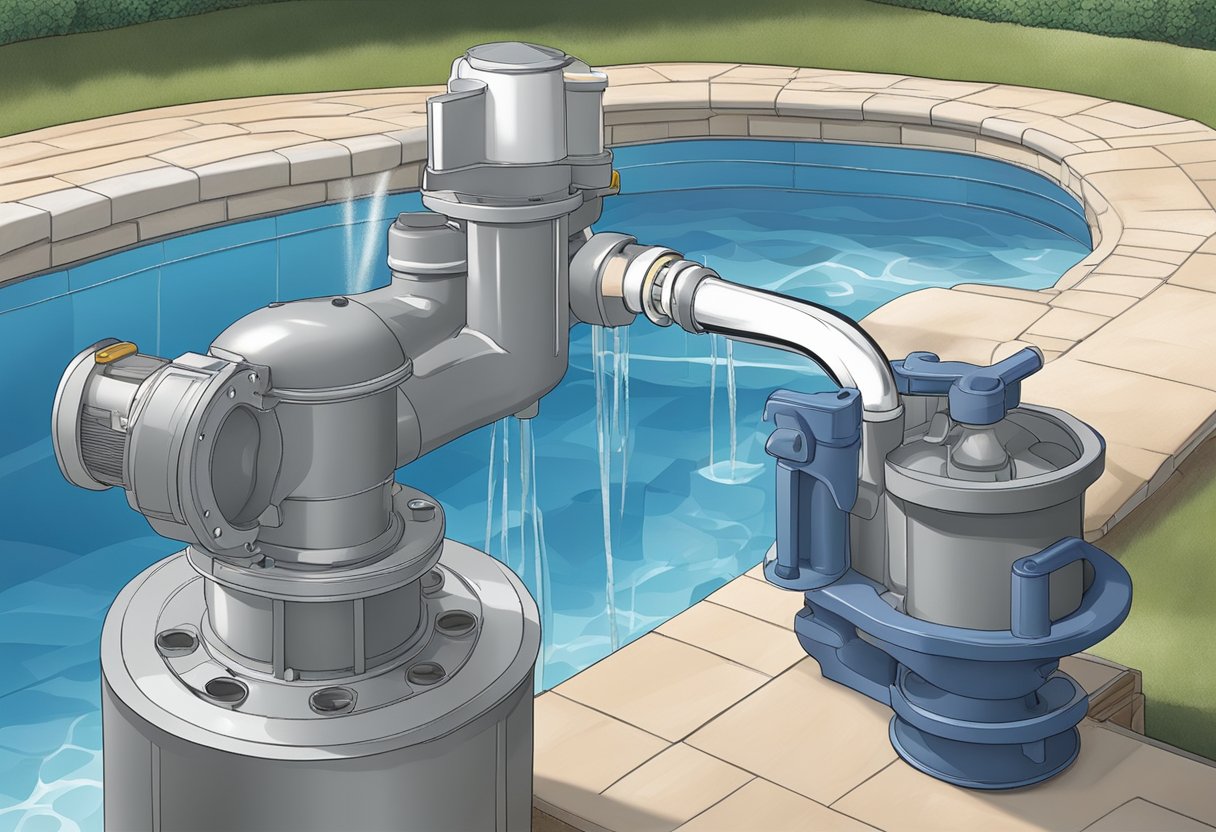

Your pool pump’s performance is vital for a well-functioning pool. Understanding and repairing flow issues and leaks ensures a healthy and clean swimming environment.

Detecting and Fixing Common Leak Points

Identify and address the usual suspects responsible for pool pump leaks to maintain optimal performance:

- Check the Pump’s Seal: The shaft seal may be the cause of a leak, particularly if you see water dripping underneath the pump. When the seal is worn out, it allows water to seep through. Examine the seal and, if necessary, replace it to restore proper function.

- Examine Suction Line: A leak in the suction line can bring air into the system, affecting water flow negatively. Perform a simple test by applying a water-and-soap solution along the line and looking for bubbles, which indicate a leak. Replace or repair the compromised section promptly.

- O-Ring Integrity: The O-ring on the drain plug can become dry or cracked. If you find leakage at the plug, replace the O-ring to reseal the connection.

- Skimmer Basket Blockage: A clogged skimmer basket can restrict water flow, causing the pump to suck in air. Ensure it’s clean and clear of debris for optimal operation.

Leaks can arise from the pressure-side as well. Inspect all related areas and consult the pressure gauge to ensure there isn’t an imbalanced pressure causing issues.

Optimising Pool Filtration System

- Ensure Proper Water Level: If your pump is having flow issues, check that the water level reaches the midpoint of the skimmer opening. Topping up the water might solve the issue.

- Clean Filter and Impeller Housing: A clogged filter or obstruction within the impeller housing can severely affect water flow. Routine cleans will prevent build-up and maintain your filtration system in top condition.

- Addressing Air in the System: If you suspect your pump is drawing air, this can lead to improper functioning. Use methods such as the shaving cream test to detect any suction leaks, which present as expanding cream, and seal them immediately.

By vigilantly monitoring and maintaining these components, you ensure the robust performance of your pool’s filtration system, keeping your swim space pristine and hygienic.

Maintenance and Prevention Strategies

To keep your pool pump running smoothly, preventive maintenance is key. This involves routine cleaning, regular inspections, and timely part replacements, which can prevent issues such as clogs, noise, and overheating.

Regular Cleaning and Debris Removal

You should frequently check and clean your pump basket to avoid clogs, as debris can hinder water flow and cause your pump to overwork. Ensure your pool filter is also cleaned regularly to maintain proper filtration and prevent any strain on the pump. Monitoring water levels is crucial; they should not drop too low as this could allow air to enter the system and lead to overheating or damage.

- Weekly Maintenance Tasks:

- Empty the pump basket.

- Inspect and hose down the pool filter.

- Verify pool water level is sufficient.

Proactive Parts Inspection and Replacement

Proactive inspection of pump components such as bearings, seals, and O-rings can prevent air leaks and water from leaking into the pump body. Any signs of excessive vibration or unusual noise may indicate worn-out parts. Replace them promptly to avoid further damage. Keeping spare parts handy streamlines the process and reduces downtime.

- Monthly Inspection Checklist:

- Check for leaking: Inspect seals and O-rings.

- Listen for odd noises: May suggest issues with bearings.

- Examine for wear and tear: Look at the pump body and plumbing system.

Applying these strategies will not only extend the life of your pool pump but also ensure it operates effectively, safeguarding your pool’s overall health and enjoyment.